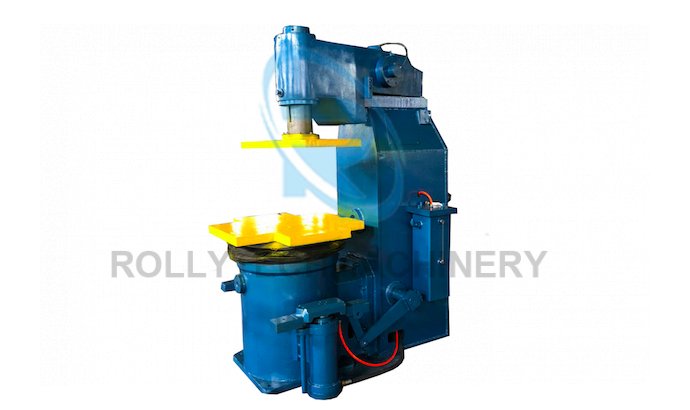

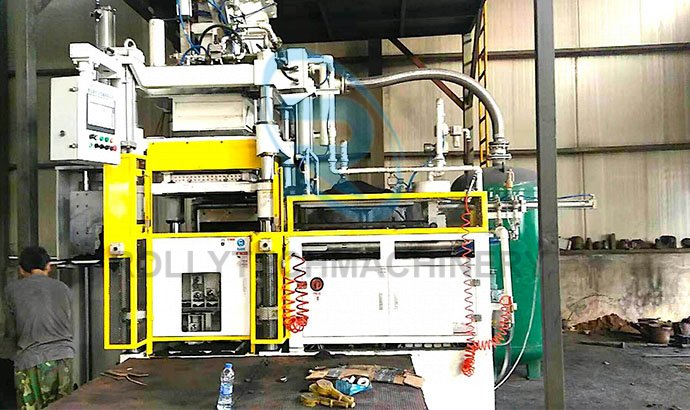

SZD multi contact molding machine is applicable to the modeling of clay sand upper and lower boxes in various casting workshops. It can be used alone or in a mechanized assembly line, or in a semi-automatic line. It uses pneumatic multi contact compaction without oil leakage, with moderate specific pressure, no special requirements for sand mold, and a large number of contacts (36-126).

It is suitable for complex model modeling and compaction. The frame is not stressed, Instead, four pull rods are hung from the side of the multi contact body to hook the workbench. As the multi contacts extend downward, the contacts compact the sand mold on the one hand and vibrate with the workbench at the same time. The sand mold has a high and uniform hardness. The sand consumption can be as small as 20-30 mm, and the sand ratio can reach h:b=2~3. The hardness of the vertical surface of the cavity can still reach more than 80. The spring fully buffered pneumatic microseismic mechanism is used, Therefore, there are no special requirements for the foundation. The connecting rod synchronous shaft structure is adopted for formwork lifting, and the air pressure oil speed regulation is adopted. The formwork lifting synchronization is good, and the speed can be controlled freely.