The line are designed with advanced technology, reliable performance, rational structure, flexible layout, simple application and maintenance. Which can meet the demand of annual 3000 - 10000 tons of resin sand castings production.

Line detailed features:

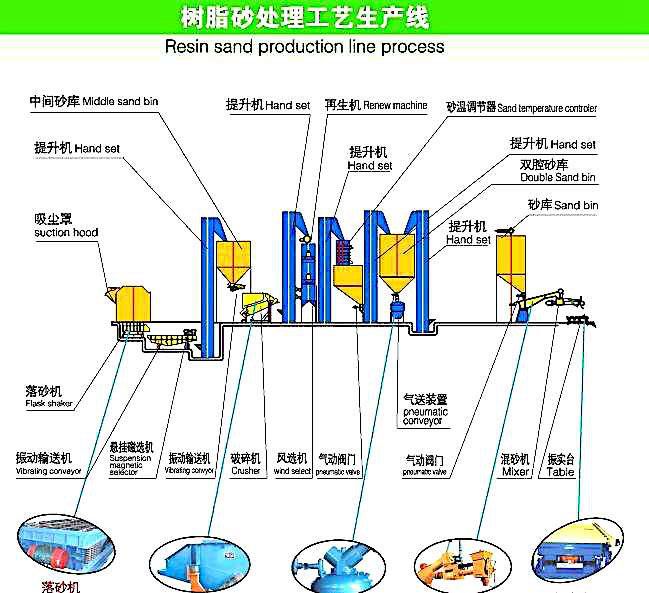

● resin sand molding production line is generally composed of preparation station, molding station, hardening station, mold lifting station, running trolley, flow coating station, surface drying furnace, lower core box station, casting cooling line, etc.

● it is applicable to the production of medium and small castings to improve production efficiency and ensure quality.

● according to the user's requirements, determine the size and load of each equipment table of the molding production line, as well as the production beat and process flow of the molding production line.

● the whole line adopts PLC centralized control, with high degree of automation and stable process.

● the motorized roller table is designed as an accumulation type, which can organize production flexibly.

● the movement of the transfer vehicle and the turnover of the turnover machine are controlled by AC frequency converter, which is stable and reliable, convenient for speed regulation and accurate in positioning.

● the whole line is equipped with a complete detection system to detect the accuracy and reliability of the core box and station board as required, and send a signal to PLC to realize automatic control.

● multiple pneumatic positioning devices shall be set on the motorized roller table to ensure that the core box or core plate is kept in the accurate position.

● the electric control system mainly includes PLC, programmer, AC frequency converter, touch screen, proximity switch without electric shock, control cabinet, etc. Several local control boxes are set on the line, which can operate all actions of the whole line manually. Emergency stop switch and fault indicator are set on the local control box.

● the casting surface is smooth, with clear edges and corners and high dimensional accuracy.

● high modeling efficiency, improved productivity and site utilization, and shortened production cycle.

● the resin sand mold (core) has high strength, good formability, lower gas generation than other organic molds, good thermal stability and good air permeability, which can greatly reduce casting defects such as sand sticking, sand inclusion, sandstone, porosity, shrinkage cavity and crack, thus reducing the scrap rate, and can produce complex and key parts that are difficult to make with clay sand.